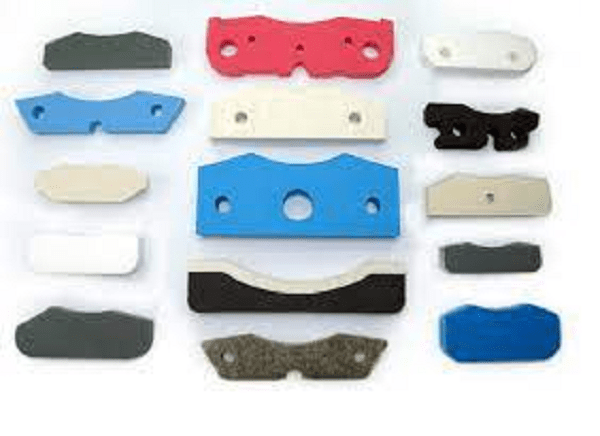

There are many types of end seals available, and the style you choose will depend on several factors, including run speed, ink type, dead band width, chamber design, and job length. End seals can be made from felt, foam, or rubber, which comes in many grades and can vary in price and effectiveness. In addition, many end seals are made from a combination of foam and plastic.

Leaking end seals are common.

The resulting oil loss can be quite dramatic, mainly if the leak is severe. The oil leak can occur when the engine has reached operating temperature or when the affected part is in motion. The low oil light will illuminate if the loss of oil exceeds the manufacturer’s specified limit. If the oil pressure light displays, the problem is likely caused by the leaking end seal.

The leading cause is the wrong end seals for flexo printing. These seals are responsible for a large portion of the loss of spot color ink. A single leaking end seal can lead to the loss of over 9,000 feet of the substrate. Fortunately, these leaks can be repaired while the press is down. During downtime, a new seal can be installed, and the damaged ink can be reused to make a difference.

They can be effective but also expensive.

There are many types of end seals available for your flexo press. The type of ink used, run speed, dead band width, chamber design, and job length determine which are the best for your needs. Foam, felt, or rubber, with different grades and compounds. Some end seals are made of plastic and foam or combine foam and plastic.

They can be made of a variety of materials.

Flexible packaging, label printing, and flexo printing require different types of seals. The materials used for flexo end seals are essentially the same, although new materials can be more durable and cost-effective. End seals are also essential to the chamber doctor blade system, so they must be leak-tight to achieve accurate doctoring results. Choosing the correct type of seal is necessary for several reasons, including less ink waste and less cleaning time. When choosing a material for a flexo end seal, you should consider the type of printing you do. For example, narrow web label printing requires a different type of seal than wide web flexible packaging production. Similarly, coating and converting require other sealing concepts, as do different materials and processes. Therefore, the sealing material you select depends on your specific production environment, the type of ink you are using, and the intended use of the seal.

They can be appropriately sized.

When selecting end seals for flexo printing, choose the right size and material. Selecting the wrong flexo end seal can result in problems with your printing. To avoid these problems, make sure to contact your supplier for assistance. They will help you choose the right flexo end seal for your print job. These are the minor components of the flexo printing process. Not all flexo end seals are created equal, and the wrong-sized one can lead to leaks. The end product will be compromised because of wasted ink. While many companies try to cut costs using generic end seals, they fail to account for these issues. By sizing flexo end seals properly, you will minimize chamber leaks. Aside from reducing leakage, they also minimize wear on

printing blades, thereby reducing the overall quality of your printing.

They can be purchased at a relatively low cost.

When you choose the right flexo to end seal, it is essential to consider factors like the length of run, the type of ink used, and the press speed. In addition, you must choose the suitable material, as the suitable material will affect the life of the seal. For example, different types of rubber and foam are available in various grades, and the proper molding temperature can affect their performance.

Compared to felt end seals, flexible foams are more durable and have a lower cost. The new foams are also much less expensive and last just as long. Several flexo end seal materials include polyurethane foam, rubber, and PVC. Some of them also have different compression ratios and durometers. So, you should be able to find a suitable material for your specific application at an affordable price.